Conformal Coating Types: Resources and Guide to Get Started

Conformal coatings provide electrical insulation and protect electronic components from environmental risks such as corrosive or chemical exposure. There are five types to consider: acrylic, silicone, epoxy, urethane, and Parylene. Choosing the correct one is critical. Each has different properties, benefits, and drawbacks, and the material you choose will affect many aspects of the and, consequently, the manufacturing process.

This guide provides resources to understand which conformal coating type is best for your requirements with an overview of each material and the processes that will be affected most by your decision.

As you read this guide, keep the following questions in mind:

What environmental threats will be in the operating environment?

What type of conformal coating standards does the material need to meet?

Is a particular coating thickness required in the project specifications?

Are simplicity and cost priorities, or is reliability most important? Is it a combination?

The answers to these questions will provide the context you need to understand which coating will best fulfill the purposes of your project.

Conformal Coating Types

Each conformal coating type has a unique chemical composition that leads to distinct properties. The coating materials vary in cost and influence your choice in the application process. Additionally, a coating’s properties can affect procedures such as removal or repair. For example, a robust, chemically-resistant coating may be harder to remove. Each type is summarized below.

Acrylic Conformal Coating

Acrylic films are generally the easiest to apply and work with throughout the coating process. For example, acrylic removal is relatively easy. These coatings are a transparent, robust, affordable option for moisture protection, fungus resistance, acid/base protection, and dielectric strength.

Notable Acrylic Properties

- Clear protective coating

- Relatively short drying times

- Good electrical and physical properties

- Low moisture absorption

Acrylics are one of the simplest coating types to apply, and the films dry quickly. Application methods include brush, spray, and dipping. The simplicity of the coating process and the ability to use less expensive application methods make acrylics a good solution for applications that require lower manufacturing costs and less manufacturing time.

Silicone Conformal Coating

Silicone films protect components and can act as a shock and vibration absorber to relieve parts from physical stress. Silicones perform well in extreme temperatures, remaining stable at -65°C to 200°C, and are resistant to ultraviolet and ozone degradation.

Notable Silicone Properties

- Good humidity and moisture resistance

- Low toxicity

- Easy to apply

- Easy to repair

Silicone can be applied with dipping and spraying methods or simple flow coating. Silicone is reasonably easy to repair and, due to its excellent heat cycling performance, is appropriate for automotive, aerospace, and industrial environments. However, moisture may permeate through the coatings, and can exhibit poor mechanical strength.

Epoxy Conformal Coating

In addition to safeguarding components with resistance to abrasion, corrosion, harsh chemicals, oil, and thermal shock, epoxy coatings serve various purposes. For example, thermally conductive epoxy protects printed circuit boards with components that may give off heat. Meanwhile, flame-retardant epoxy is helpful for fire hazard protection.

Notable Epoxy Properties

- Very robust, difficult to remove

- Excellent chemical and abrasion resistance

- Very rigid conformal coating

- High dielectric strength

Epoxies are easily applied and may be a two-part compound or a single compound to be cured with UV or heat exposure. Dip-coating, brush, or spray methods are suitable for epoxy application. Film shrinkage also may occur during polymerization, potentially causing issues during the coating process, and the toughness and durability of epoxy may damage products if rework or removal is necessary.

Urethane Conformal Coating

Urethane coating material forms tough, hard coatings with strong solvent and abrasion resistance. These sturdy films serve as a barrier to air-borne contaminants and may be a good option for mitigating the growth of tin whiskers.

Notable Silicone Properties

- Moisture and oil resistance

- Fungicidal

- Good flexibility

- Class F temperature rating (160°C/320°F)

Urethane films can be applied by dipping, spraying, or brushing, and curing is required to finalize the coating after application. Curing may take an hour to several days, adding another step to the polyurethane coating process.

Parylene Coating vs. Conformal Coating

Unlike acrylics, epoxies, urethanes, and silicone coatings, Parylene is deposited through chemical vapor deposition (CVD). This vacuum deposition process requires specialized equipment that may have limited capacity, raising cost and production time challenges. Additionally, due to the CVD method, Parylene coats anything it touches in the coating chamber, typically requiring a masking process. On the other hand, Parylene films do not require curing, and unlike other coating methods, the CVD process does not entail any VOCs, solvents, catalysts, or disposal. If reliability is a priority over cost and efficiency, Parylene is a good choice. It is also possible to find Parylene coating suppliers that specialize in mass production and cost-effectiveness, such as HZO.

ACRYLIC (AR) COATING PROPERTIES

EPOXY (ER) COATING PROPERTIES

SILICONE (SR) COATING PROPERTIES

URETHANE (UR) COATING PROPERTIES

PARYLENE (XY) COATING PROPERTIES

Conformal Coating Method

If you have chosen your material, the next step is to select from the available application methods.

To choose the best method, consider:

THROUGHPUT REQUIREMENTS

REQUIRED PERFORMANCE

CAPITAL EQUIPMENT

SUBSTRATE COMPLEXITY

Brush coating is the easiest and cheapest application method and requires minimal maintenance. Equipment is less costly, and there may not be as much masking needed due to the controlled nature of this technique. However, the quality and results of the brush conformal coating procedure are operator and tool dependent and may therefore vary in quality and conformability. Contamination issues may also be a concern.

ADVANTAGE

DISADVANTAGE

The spray coating technique can be manual or automated, and faster than brush coating. Spraying can produce consistent results, provided several parameters (pattern, solvent dilution, nozzle pressure) are correctly combined. However, PCB spray methods entail more masking time than brushing methods. Spraying is less expensive than other methods, but humidity and temperature conditioning are required and factor into startup costs.

ADVANTAGE

DISADVANTAGE

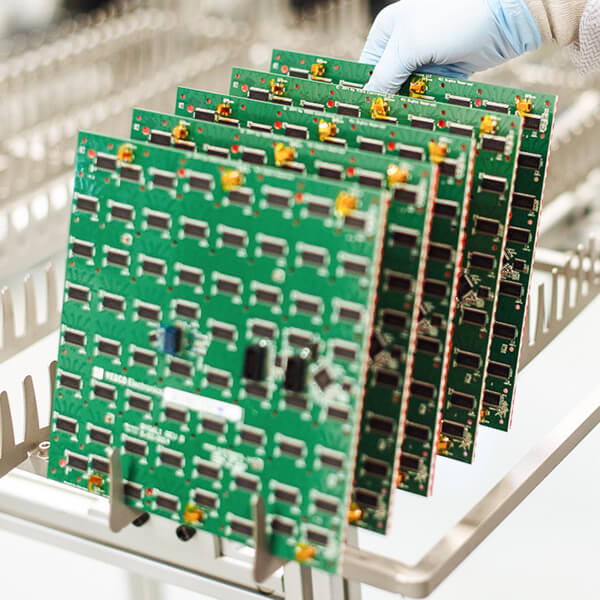

Like spraying, the dipping may be automated or manual and is an effective way to coat components that are not too irregular or bulky in shape. The dip coating method completely encapsulates electronics and can be an efficient, low-cost process for high-volume applications. With proper implementation, dipping produces repeatable film thickness and uniform coverage. However, to avoid contamination, the material in the coating dipping machine must be purged and replaced periodically, increasing cost and complexity.

ADVANTAGE

DISADVANTAGE

Of the coatings listed, Chemical vapor deposition (CVD) is used exclusively with Parylene coatings. The CVD process is performed under vacuum, with specialized equipment that includes a coating chamber. All surfaces can be coated evenly regardless of chamber position, and the coating deposits the same relative thickness on the objects being coated. This vapor phase coating process also leads to pinhole-free coatings, absent of defects. Masking and demasking are typically required, but no curing is necessary.

ADVANTAGE

DISADVANTAGE

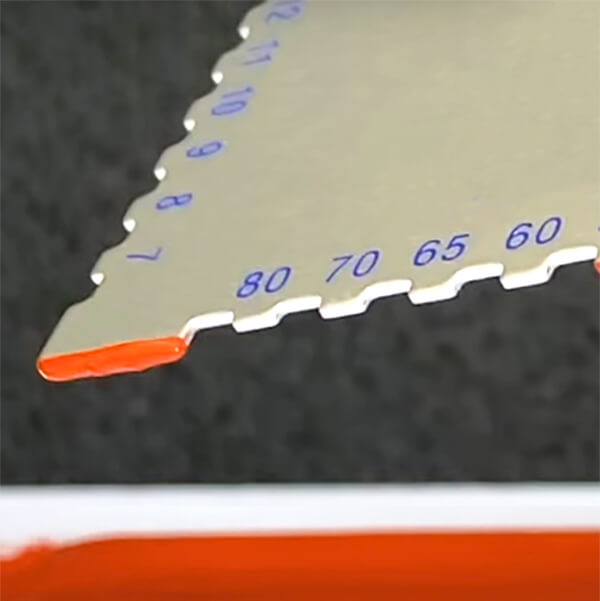

Coating Thickness Measurement

Coating material impacts thickness due to different material properties. For example, Parylene can pass IPC CC-830C at 50% film thickness of other coating types, while other coatings must be applied in thicker layers to meet standards adequately. Accurately meeting the requisite thickness is crucial. If the coating is too thin, components remain vulnerable to the environment. However, if it is too thick, the insulating properties of the coating may render specific parts non-functional.

HOW TO MEASURE CONFORMAL COATING THICKNESS:

Several methods measure conformal coating thickness, including:

- Manual measurement

- Measuring Wet Coating with a coating thickness gauge

- Measuring Dry Coating

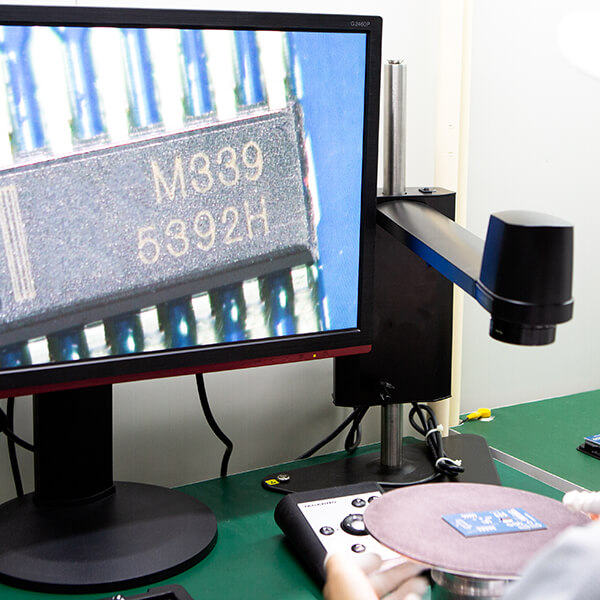

Conformal Coating Inspection

After the coating process is complete, components should be inspected for criteria based on customer requirements and coating standards. The conformal coating type may influence the inspection process, as different materials may be chosen to meet various standards and thicknesses and may need to meet varying levels of reliability.

Read the IPC A 610 Standards for Conformal Coating Inspection

Conformal Coating Masking and Demasking

Masking prevents coatings from being applied to components that need to be uncoated to function (for example, connectors). Successful masking entails selecting the correct masking materials, tailoring the masking process to the coating application process, and choosing the best masking techniques. After the coating application is complete, the masking is removed with the demasking process. Masking and demasking can be more complex and critical with certain coating materials. Additionally, some application methods require more masking and demasking time than others. Therefore, the best masking processes are tailored to the material.

Conformal Coating Removal

It is necessary to remove coating from time to time due to poor adhesion, wrong choice of materials, repairs, or other reasons. Removal can add cost and complexity to the coating process, and the type of coating you choose will influence which removal methods are best.

TECHNIQUES INCLUDE:

- Peeling

- Chemical Solvent

- Grinding and Scraping

- Thermal

- Micro Sandblaster

Curing

Conformal coating curing is a process that causes cross-linking so that the film can reach its optimum properties. Curing is distinct from conformal coating drying, when a coated component is fit to be handled. Coating types require different drying and curing methods, with one exception. Due to its CVD coating process, Parylene does not require drying or curing.

METHODS INCLUDE:

- Moisture

- Conformal coating UV cure

- Oxidative

- Heat

- Catalytic cure mechanisms

- Condensation

Coating Resource Center

Need more information? Check out our resources below.

Choose Best Conformal Coating

Conclusion

This guide has touched on the concepts you need to understand to get started, but has only scratched the surface of all you need to know. We recommend “Coating Materials for Electronic Applications: Polymers, Processing, Reliability, Testing (Materials and Processes for Electronic Applications,” written by James Licari as an excellent in-depth resource. Additionally, you can browse our resource center and read more, download a technical paper, or listen to one of our engineers speak about coatings in an on-demand webinar.