Parylene Coating Services

Parylene is a chemical substance deposited as a film at the molecular level through a vacuum deposition process. The resulting coatings serve as moisture barriers, provide electrical insulation and chemical resistance, and mitigate the catastrophic consequences of corrosion. Parylene is much thinner than other conformal coating materials with uniform coverage over the surface of a product, making it the coating of choice for applications when reliability is a priority.

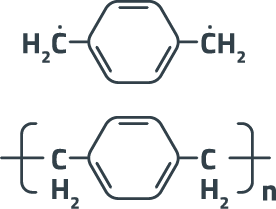

Chemical structure of the active Parylene N monomer that enters the deposition chamber.

What are the Benefits of Parylene?

COST REDUCTION

Reduce reliability-related repairs resulting from corrosion or water damage that leads to refunds, warranty claims, and service calls

Minimize product recalls and product liability

Lower total cost of ownership with long-lasting, durable protection

RISK MITIGATION

Reduce risk of corrosion damage from exposure to humid, salty, sulfurous, and other harsh environments

Reduce risk of damage due to solvents and water exposure

Reduce risk of electrical failure due to foreign object debris (FOD) and metal whiskers

Reduce risk of dendrite formation /electrochemical migration (ECM)

Minimize water absorption in humid environments

IMPROVED RELIABILITY

Imparts low stress to solder joints, especially during thermal cycling

Has very low levels of outgassing, which is critical for satellite and extreme remote sensing applications

Low history of service required in high-reliability applications, especially in aerospace, defense, and medical device applications

Promote durability of products, the occurrence of uptime, and employee and consumer safety

OPTIMIZED FUNCTIONALITY

Easily meet corrosion protection, dielectric, thermal, and chemical resistance requirements

Help with lightweighting products for improved fuel and energy efficiency, as well as overall mechanical stability, for aerospace, automotive, billboard, and large display applications

Excellent biocompatibility and biostability

Help products meet industry standards including ASTM, FDA, IPC, ISO, JEDEC, MIL, UL, and more

What is the Parylene Coating Process?

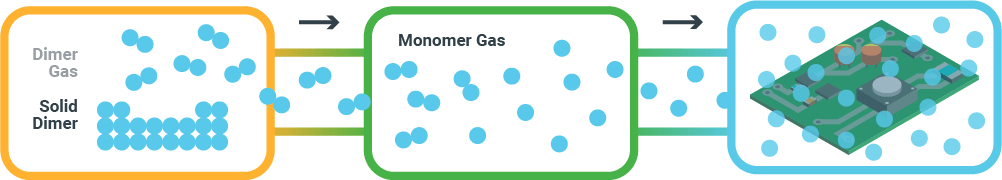

Parylene is applied with a distinctive deposition method known as chemical vapor deposition (CVD). While HZO may tailor other processes to particular use cases and applications (such as adhesion promotion or surface cleaning), the CVD process is repeatable. CVD takes place under vacuum and involves the following steps:

- Heating a precursor material until it sublimes from a solid to a gas

- The precursor gas is heated much hotter to activate and form the reactive monomers

- Within the deposition chamber that is close to room temperature, the monomers enter and land on everything inside

- As more monomers land near each other, they connect and form the polymer coating

- The thickness of this polymer film typically ranges from around 2 to 25 microns

As Parylene deposits molecule by molecule at around room temperature, the CVD polymerization results in complete even coverage without applying thermal stresses to products, and has even enveloped and protected fragile wire bonds. As a result, Parylene coatings are highly reliable.

Conventional conformal coatings may require 50 to 250 microns of thickness, or even more, to attempt to achieve Parylene’s performance.

The Parylene deposition process does not require a catalyst, hardener, or subsequent curing. No by-products are released during polymerization.

Parylene Coatings at the Core of Trusted Products

Parylene Coating Properties

Material Properties

Parylene films are notable for their material properties, including excellent dielectric performance, good abrasion resistance, superior chemical resistance, and low thermal expansion.

Coating Attributes

Parylene’s chemical vapor deposition (CVD) process results in pinhole-free coatings with consistent thickness and true conformality.

Meets Sustainability Regulations

There are no initiators or catalysts in the polymerization process, so the coating is free from trace ionic impurities, and is also REACH, Restriction of Hazardous Substances (RoHS) Directive, PFOA/PFOS-free, and California (CA) Proposition 65 compliant.

Parylene Coating Properties Include:

- Insoluble to common chemicals and conditions

- Superior barriers to moisture and chemicals

- Complete conformality on all exposed surfaces, corners, and edges

- Defect-free

- Free of solvents, residues, and catalysts

- Dry film lubricity

- High dielectric strength

- No outgassing

- No curing

- Biocompatible, biostable, can survive exposure to chemicals in and on the human body

- No thermal stress

- Optically clear and colorless

- Environmentally friendly

- Adheres to a variety of substrates, including plastic, metal, etc.

Parylene Types and Uses

Parylene comes in several varieties, each with unique properties, ensuring a Parylene for virtually any application. Parylene types include:

Parylene F-VT-4 – Highly crystalline, excellent dielectric, very low friction coefficient, ideal for applications that entail exposure to elevated temperatures

Parylene N – Excellent dielectric, halogen-free, suitable for applications where sustainability is a priority

Parylene C – Most widely used, lowest permeability to moisture and gas, ideal for components exposed to corrosive substances

Advantages of Various Parylene Types

ATTRIBUTES

PARYLENE C

PARYLENE N

PARYLENE F (VT-4)

Is Parylene Right for my Application?

Parylene is used in various applications, including:

“Working with HZO has been invaluable to us. We can now produce reliable outdoor LED (Light Emitting Diode) signage performance that our customers around the world can depend on.”

– Donald Szczepaniak, Chief Executive Officer, PRISMVIEW

FAQ

Although there is no way to determine how much Parylene coatings would cost for your specific application without a detailed consultation with one of our engineers, in general, coating thickness, the level of product complexity, and batch sizes all can affect pricing.

Consider the Total Cost of Ownership and Other Factors

The upfront pricing of coating is not indicative of the lifetime value of Parylene. It is vital to consider the cost of a coating and coating process against a product’s end-use environment and the cost of failure. As such, Parylene is cost-competitive with other high-quality coatings and lowers the overall total cost of ownership.

When you work with HZO, we can configure a Parylene coating process in a timely manner and get you up and running soon. While every application varies due to unique needs, the image below depicts a typical timeline.

HZO PARYLENE PROCESS

PRE-PRODUCTION

Masking of areas where protection is not needed can be fully or semi-automated or performed manually by Parylene experts

Integrating Parylene into your production process entails many complex considerations and can be a time and resource-consuming process if you do this independently. You will have to ensure your printed circuit board assemblies (PCBAs) are appropriately suited for the CVD process, determine the best course of masking and demasking for Parylene, and ensure you have performed proper surface preparation. Then there are inspection, reworking, and repairing, not to mention manufacturing floor and process flow considerations. So, while coating your products with Parylene is possible, it may be more reasonable from a cost, time, staffing, and other resources perspective to work with a Parylene services provider.

People

Our engineers have an understanding of what it means to put your project in their hands. With domain experience, materials science expertise, and industry and market knowledge, they will work towards a prescriptive solution in a close partnership with your team.

Convenience

Our highly configurable Parylene coating process can be quickly assembled in a variety of settings. We offer many business models that revolve around your convenience, including factory-in-factory (FiF), and coating-as-a-service (CaaS), so your team can get back to doing what it does best – innovating products.

Equipment and Cost-Reduction

Our industry-leading automated and semi-automated masking equipment reduces labor hours associated with complex masking jobs.

Equipment and Cost-Reduction

Our industry-leading automated and semi-automated masking equipment reduces labor hours associated with complex masking jobs.

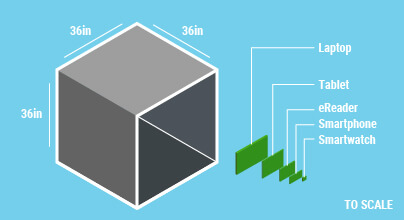

Ability to Expand the Scope of Parylene to Unique Markets

Because of our unique benefits, we can serve customers in markets requiring scalability, faster production, and lower costs. With our help, engineers developing consumer electronics (such as a personal computer) and wearable medical devices have benefited from “Total Coating Solutions” and Parylene’s superior protection capabilities.