NEMA Enclosure Ratings vs. IP Ratings: Do You Have to Choose?

Mallory McGuinness | April 14, 2021

Once upon a time, computers only sat perched on desktops, but that is no longer the case. Deployed in harsh industrial, medical, automotive, and consumer household environments, electronics must now withstand exposure to water and liquids ranging from “condensing” moisture to total submersion. They must reliably operate despite threats posed by humidity, corrosives, and other outdoor contaminants.

To assure your customers that your electronic products can dependably withstand these challenges, you most likely need to meet reliability standards, namely Ingress Protection (IP) Standards or National Electrical Manufacturers Association (NEMA) Protection Ratings. These systems classify an enclosure’s protection level from harmful elements by defining protection posed by solids and liquid ingress. It is crucial to select the correct standard to assure your clientele that the product you offer will be reliable in specific environments. This choice can be complicated because it is impossible to compare NEMA and IP ratings directly, but alternative solutions may eliminate the need to select one or the other.

IP vs. NEMA Rated Enclosures

Any comparison of IP and NEMA ratings will only be approximate. An IP Rating only considers enclosure protection against ingress of water and solid foreign objects. Meanwhile, NEMA ratings take these factors into account, as well as other hazards such as corrosion. So while you can say a NEMA type is equivalent to an IP rating, it is impossible to say that an IP rating is equal to a NEMA rating. Additionally, the two systems use different test parameters to define the level of protection, so there is no easy conversion.

NEMA Ratings

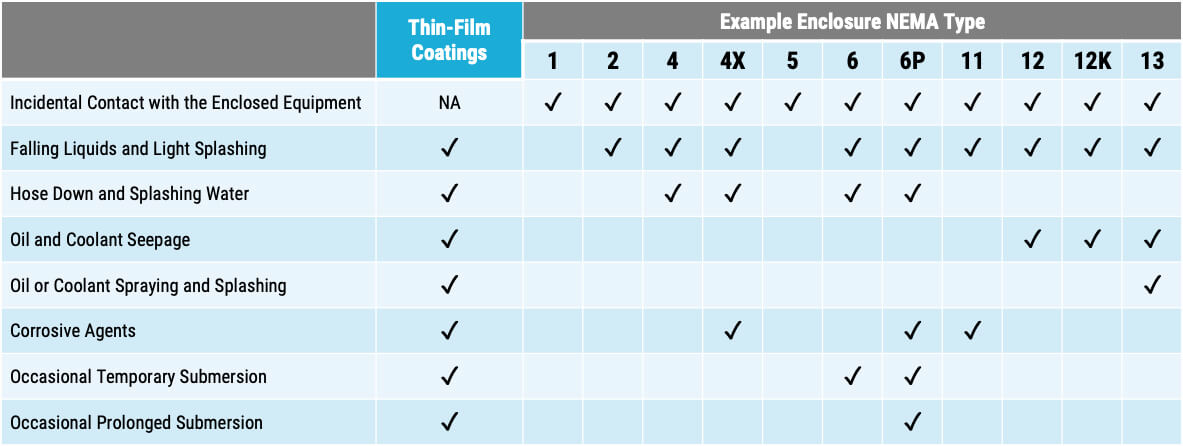

NEMA electrical enclosure ratings have numeric values, sometimes followed by a letter. Each rating corresponds to the types of hazards from which an enclosure must protect its interior and may indicate indoor or outdoor use.

You can explore a quick guide to specific NEMA ratings here.

When choosing a NEMA enclosure type, it’s essential to consider both the environmental hazards the interior needs protection from and the enclosure location to use NEMA ratings appropriately. For example, a NEMA 4 rating is a popular option because it accommodates outdoor environments and multiple weather types. NEMA rating 4X features watertight seals, corrosion resistance, and protection from dust for more extensive protection.

IP Ratings

IP ratings may be designated by two or three numbers corresponding to protection from solids, liquids, and impacts. If a device does not have a specific rating, X replaces the number. The first number signifies the size of the object that the enclosure prevents from entering. The higher the value, the more protection from solid ingresses, such as windblown dust.

The next value indicates liquid ingress protection, with digits ranging from zero to eight, with increasing amounts of protection as the numbers increase. Finally, the third value corresponds to the amount of mechanical impact an enclosure can withstand. In some electronic products, this value may not be present because most codes do not require its presence.

A short guide to IP specifications can be found here.

Read our IP checklist.

Rethinking Enclosure Standards

IP or NEMA standards may not be the best indicator for the degree of protection you need. For example, while IP liquid ingress testing works in the lab, it may not perform the same in real life. But chances are, you will still need to demonstrate your product can meet these standards to meet customer specifications.

Thin-film coatings can be an easy and efficient way to meet both NEMA and IP liquid ingress standards. These polymeric barriers protect from the inside out by direct application to components and PCBAs. They are lightweight and thin, helping you eliminate seals, and therefore, excess bulk and weight. The protective coatings also blend into the product so you can offer aesthetically pleasing, ergonomic, and functional products easily. Thin-film coatings can be used in a two-phase approach to protection that is failsafe and can help you save money and time customizing enclosures.

HZO Coatings and Relevant Standard Equivalents

Download our industrial fact sheet

Thin-film coatings can be an easy and efficient way to meet both NEMA and IP liquid ingress standards.

Contact Us

HZO offers thin-film coatings to protect your electronic products. We focus on tailored solutions to your protection requirements and can help you exceed liquid standards easily with proven solutions, no testing required. Download our datasheets, or send us a message for a consultation.

Mallory McGuinness

Discover how HZO can protect your product