Parylene Biocompatibility Properties

As a long-proven biocompatible material, Parylene conforms to ISO-10993 and is USP Class VI implantable material. Its properties make it ideal for biological and medical applications, with additional benefits that make it a natural choice for healthcare applications. Learn more about Parylene biocompatibility and other benefits the coatings provide for medical devices.

Parylene Biocompatibility

Parylene comes in various types, including Parylene C, F (AF-4), and Parylene N, and the material has long been used as a protective medical device coating. A biocompatible material will not negatively interact with living tissue. Additionally, it is physiologically non-reactive and isn’t toxic. Parylene is chemically inert, so it can survive exposure to chemicals in and on the human body (such as implantable devices) without reacting with these chemicals.

Due to Parylene’s chemistry and structure, it is biocompatible, and it meets the United States Pharmacopeia’s (USP) highest standards for biocompatibility certification, Class VI standard. Parylene has passed the USP’s stringent testing process described here and has a proven track record of reliable performance in the medical device industry,

Learn more about other ways Parylene is used

Download the HZO Parylene datasheet

Benefits of Parylene for Medical Applications

In addition to chemical biocompatibility, Parylene conformal coating has many other properties that add value to medical devices. As a low-friction polymer coating, Parylene is a dry lubricant and allows easy sliding. Because increased friction can make a medical procedure more painful and timely, this slickness is an essential benefit for medical implants.

With a mission-critical device such as an implant, long-lasting protection against enzymes, bodily fluids, lipids, and proteins is paramount. Parylene can last for decades and has exceptional barrier properties that lead to superior corrosion resistance, excellent chemical resistance, and robust protection against liquid ingress.

Parylene is odorless and transparent, minimizing irritation, and does not require catalysts, initiators, or curing to be deposited, avoiding impurities that could disrupt its unique benefits. It also maintains protection throughout a wide temperature range.

With precise control, Parylene thickness is minimal – 50% of traditional conformal coatings, with pinhole-free coatings that exhibit high dielectric strength.

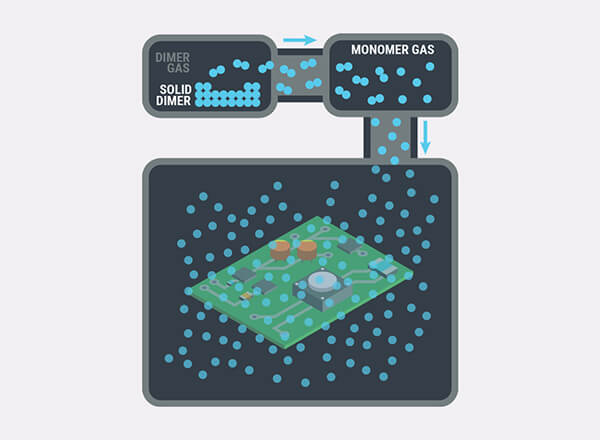

Chemical Vapor Deposition Process

Parylene’s vapor-based deposition process creates a truly conformal, even coating desirable for applications where reliability is a priority. The highly repeatable process generates consistent results and minimizes coating defects. Several CVD services are available, including purchasing CVD equipment for sale. However, without the help of dedicated experts, endeavoring to coat your devices with Parylene can be a timely, cost-consuming process. With improper application, Parylene removal may even be necessary.

Learn more about Parylene pricing

Illustration of the CVD Process

Read More about the CVD process

HZO Medical Coatings

As a Parylene coating company, HZO focuses on more than just producing dependable, consistent coatings. We aim to simplify the coating process with a turnkey solution, several business models, techniques, Parylene masking automation, and Parylene coating equipment to drive down costs and make the CVD process scalable.

These benefits allow us to extend the scope of Parylene for medical devices to connected devices worn on the body, such as smartwatches, continuous glucose monitors, activity trackers, and hearing aids. With our engineers’ domain experience, we specialize in coating for the Internet of Medical Things. We believe in Parylene’s capacity to improve these critical devices that ordinarily would not be candidates for coating due to cost and scalability concerns.

If you are interested in speaking to a team member about HZO medical coatings, please get in touch with us today for a consultation.

Discover how HZO can protect your product