Parylene C Datasheet (PDF Download) – Properties Explained

Parylene conformal coatings come in various types, including Parylene C, Parylene N, and Parylene F (VT-4), and have decades of trusted performance in critical industries and applications. The coating is often superior in barrier properties, uniform coverage, and performance, with less stress on mechanical structures, as a Parylene datasheet indicates.

Parylene coatings have good optical properties, are comparably thinner than conventional conformal coatings, and add virtually no weight to components and products. Parylene’s coating thickness can pass tests such as IPC CC-830C at 50% of the film thickness of other conformal coating materials.

Parylene coatings are unique in their ability to be polymerized and deposited by chemical vapor deposition (the Parylene coating process) onto components maintained at room temperature. As a result, the coatings are high purity, free of defects and pinholes, and ideal for meeting many electronic product design reliability requirements.

Parylene C is biocompatible, highly resistant to moisture, vapor, and corrosive gasses, and exhibits strong chemical resistance. Because of these strong anti-corrosion properties and a valuable combination of properties for most applications, from medical devices to personal computers. Parylene C is used for most products that need a conformal coating for protection.

Learn more about why Parylene is used

To see the specific properties of Parylene C, you can download HZO’s Parylene datasheet below, under the column of HZO Guardian Plus™, our Parylene C offering. For reference, HZO Guardian Zero™ is our Parylene N coating solution, suitable for halogen-free applications.

Parylene Datasheet

Download HZO’s Parylene datasheet

For reference, a short description of each category property in the Parylene datasheet is provided, and some descriptions of tests used to acquire data as well as explanations as to why some data points might be vital for your application.

Parylene Physical and Mechanical Properties

Parylene is a crystalline polymer that results in generally high mechanical strength. Compared to other polymer coatings, it has a relatively high tensile and yield strength, and wear resistance is substantial. An explanation for some Parylene datasheet properties is below.

Parylene C Young’s Modulus

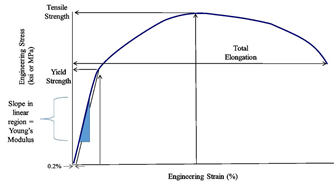

Young’s modulus is a mechanical property that measures the stiffness of a solid material. Young’s modulus is the elongation of a material under unit stress when the deformation is elastic.

The image below depicts an example stress-strain curve which shows the change in stress as strain increases and identifies the Young’s modulus and Tensile strength

Young’s modulus is the slope of the linear part of the stress-strain curve for a material under tension or compression. In other words, the strain will be proportional to stress. There is no permanent deformation either. The material will behave like a spring and return to its original dimension on the removal of load.

Tensile strength is is the maximum stress a material can withstand. Meanwhile, Elongation to Break is the ratio between changed length and initial length after breakage of test specimen.

Image Source: https://www.thefabricator.com/thefabricator/article/metalsmaterials/the-differences-between-stiffness-and-strength-in-metal

The table below shows values for Young’s Modulus and Tensile Strength for Parylene C and N and polyester and polyamide.

Table 1: Young’s Modulus and Tensile Strength for Parylene C and N and Polyester and Polyamide

| Material | Young’s Modulus | Tensile Strength |

|---|---|---|

| Polyester | 7.1×105 psi MD | 29,000 psi MD |

| Polymide | 3.6×105 psi | ~33,500 psi |

| Parylene C | 4.6×105 psi | 10,153 psi |

| Parylene N | 3.5×105 psi | 6,526 psi |

Parylene C Electrical Properties

Parylene doesn’t conduct electricity, an essential trait for a film that coats and separates conductive areas on electronics. As the Parylene datasheet indicates, it is a superior electrical insulator (dielectric) coating since it coats every surface on a product with uniform thickness. Although conformal coatings aren’t meant to be used as the primary means of electrical insulation, they can isolate electrical ground from active traces and supplement other insulation forms. The lack of pinholes and other point defects helps Parylene prevent arcing.

A coating with variable thicknesses on an electronics assembly running at high voltage may have a greater risk of failure if the device operates near the dielectric breakdown voltage of the coating. The coating undergoes a complete failure at the breakdown voltage, and any insulative properties are left negligible or lost entirely.

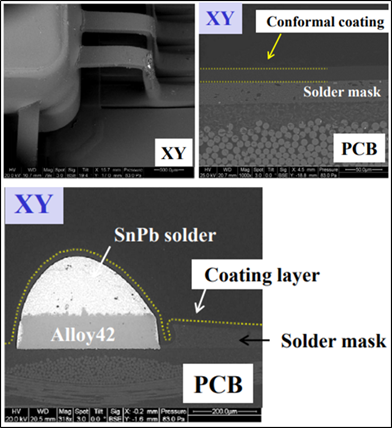

An example of how Parylene deposits is depicted below:

Courtesy of CALCE, University of Maryland

Though defined by its fundamental composition, the insulating properties of a Parylene coating increase with thickness. By selecting a specific Parylene thickness, you can fine-tune electricity-blocking properties. Since each Parylene type has different dielectric properties, there’s a suitable parylene for virtually every application.

Parylene Dissipation Factor

Dissipation factor is the reciprocal ratio between the insulating material’s capacitive reactance to its resistance (Equivalent Series Resistance or ESR) at a specified frequency.

This property measures electrical energy lost and absorbed (power dissipation) when an electrical current is applied to an insulating material. Much of the absorbed energy is dissipated as heat—the lower the dissipation factor, the more efficient the insulator system. Dissipation factor is an essential property because it can be used to maximize power delivery.

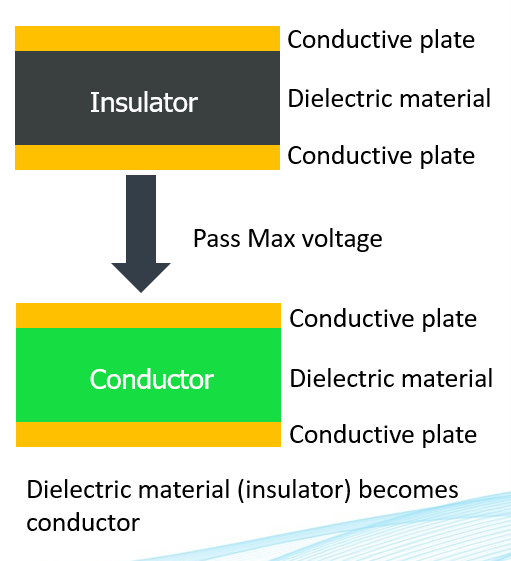

Parylene Dielectric Strength

Dielectric strength is defined as the maximum voltage required to produce a dielectric breakdown through the material and is expressed as Volts per unit thickness. The image below shows that the original dielectric material as an insulator becomes a conductor because the dielectric material passes the maximum voltage and produces a dielectric breakdown.

Dielectric strength is important for higher voltage design because it prevents arcing and protects against high voltage from static electricity. Please refer to the Parylene datasheet to see the values for this property.

Learn about Parylene removal considerations

Parylene C Dielectric Constant

Dielectric constant is the ratio of permittivity of a substance to the permittivity of free space.

Dielectric Constant (k) = ε / ε0

A sample is placed between two metallic plates, and capacitance is measured to obtain these values. A second run is measured without the specimen between the two electrodes. Dielectric constant is the ratio of these two values, and a low dielectric constant is essential for rapid signal propagation.

Parylene Thermal Properties

Parylene coatings have temperature limits that, when reached, shorten the coating’s usefulness. You will need to know your expectations and/or specifications for the product’s end-use environment if you need to mitigate risks associated with high-temperature applications. The temperature stability values for the parylenes are collected in the table below and are based on industry literature.

Table 2: Parylene Thermal Properties

| Parylene Type | Long-Term Temperature Limit (°C)

Duration=~10+ Years |

Short-Term Temperature Limit (°C)

Duration=~1 Month |

Melting Point Temperature (Tm) |

|---|---|---|---|

| Parylene N | 60 | 96 | 420 |

| Parylene C | 80 | 115 | 290 |

Fortunately, the Parylene c melting temperature is high, at 290 °C. Parylene N maintains performance through temperatures even more extreme.

Read more about Parylene temperature range

Parylene Barrier Properties

Parylenes are hydrophobic, ultrathin, lightweight, and highly conformal, wrapping around every edge available, where the coating deposits the same thickness around the components they coat. The vapor phase coating process leads to pinhole-free coatings that are also free from defects. In addition, the coatings trap and immobilize any particles that may be present on substrates.

The polymer chains pack tightly against one another, making Parylene resistant to chemicals passing through the coating and reacting with the coating itself. Parylene is impervious to moisture and insoluble in chemicals found in most end-user and industrial environments. The coating also does a good job of blocking gases that can lead to corrosion of the coated object.

The Parylenes provide an excellent physical barrier that protects the underlying objects, especially electronics, from external contamination and electrical shorting. As a physical barrier, Parylene protects from various types of problematic contamination, such as dust, foreign object debris (FOD), metal filings, and airborne salts.

Parylene C has the best barrier properties, as indicated on the Parylene datasheet, including preventing both gas and water vapor penetration. The table below compares the Gas Permeability and WVTR of Parylene with other conformal coating materials.

Table 3: Barrier Properties of Conformal Coatings

| Polymer | Gas Permeability at 25 °C, (cc·mm)/(m2·day·atm) | WVTR,(g·mm)/(m2·day) | ||||||

|---|---|---|---|---|---|---|---|---|

| N2 | O2 | CO2 | H2 | H2S | SO2 | CI2 | ||

| Parylene C | 0.4 | 2.8 | 3.0 | 43.3 | 5.1 | 4.3 | 0.1 | 0.08 |

| Parylene N | 3.0 | 15.4 | 84.3 | 212.6 | 313 | 745 | 29.2 | 0.59 |

| Parylene F (VT-4) | – | 16.7 | – | – | – | – | – | 0.28 |

| Epoxy (ER) | 1.6 | 4 | 3.1 | 43.3 | – | – | – | 0.94 |

| Polyurethane (UR) | 31.5 | 78.7 | 1,181 | – | – | – | – | 0.93 |

| Silicone (SR) | – | 19,685 | 118,110 | 17,710 | – | – | – | – |

Ref.: Licari, James J. Coating Materials for Electronic Applications – Polymers, Processes, Reliability, Testing. William Andrew Publishing, 2003 and various companies’ literature.

Parylene C also performs well when immersed in solutions of sodium chloride salt in water. The following table shows Parylene C’s performance compared to examples of epoxy, polyurethane, silicone, and Teflon™ coatings.

Table 4: Resistance of Different Polymers to 0.9% Saline Solution

| Polymer | Coating Method | Layer Thickness (microns) | Time Until Total Breakdown |

|---|---|---|---|

| Parylene C | 60 | 25 | > 30 d |

| Epoxy (ER) | 80 | 100 ± 25 | 6 h |

| Polyurethane (UR) | Dip Coating | 100 ± 12.5 | 6 h |

| Silicone (SR) | Dip Coating | 75 ± 12.5 | 58 hr |

| Teflon | Spraying | 75 | 6 h |

Ref.: Mordelt, G., Heim, P. High-Tech-Beschichtung der Zukunft, Metalloberfläche 52(5), 368 − 371 (1998).

In general, Parylene C performs extremely well as a barrier to corrosion due to the coating’s ability to minimize the influence of the factors that affect coating lifetime and performance, including the following:

- Oxygen permeability − low oxygen permeability for a polymer coating

- Water vapor permeability − very low WVTR for a polymer coating

- Liquid water uptake − Parylene C absorbs very little water

- Ionic permeability − salts have a difficult time passing through the coating

- Coating porosity − at a thickness of just 5 to 8 microns, Parylene C forms a pinhole/pore-free coating

Watch Dr. Clancy’s webinar on proven methods of corrosion resistance

About HZO

HZO is a Parylene services provider focusing on driving down associated costs and increasing coating efficiency for Parylene’s solvent free deposition method. We have built proprietary cubed Parylene chambers that can house more substrates than any other Parylene company. Our chambers are large in size, but the cubed shape allows for high loading density, increasing throughput, and scaling for high-volume applications.

We have also built equipment to automate Parylene masking and demasking to cut costs, save on labor, and decrease the risk of quality issues due to manually doing these processes.

To learn about Parylene pricing for your next project, contact us today. To learn about our proven track record, read our case studies.

Discover how HZO can protect your product