Complete Guide to Polyurethane Conformal Coatings for Electronics

Mallory McGuinness | June 23, 2020

Conformal coatings are polymeric materials applied to a PCB to improve device reliability. These films protect electronics from environmental threats, including humidity, liquids, and corrosive substances.

Different conformal coating materials include acrylic, silicone, epoxy, and Parylene. Polyurethane is another common conformal coating material.

Learn how to choose the best conformal coating

What is Polyurethane Conformal Coating?

Urethane coatings are tough, hard protective layers resistant to solvents and abrasion.

Polyurethane conformal coatings have the following attributes:

- Moisture and oil resistant

- Fungicidal

- Good flexibility

- Can be thinned to achieve a chosen viscosity

- Class F temperature rating (160°C/320°F)

-

Retain excellent electrical insulation properties after the MIL-I-46058 cycling test

Polyurethane Conformal Coating Benefits

Polyurethane can augment devices, extending their lifetime and ensuring that they dependably operate no matter where they are deployed.

These coatings exhibit sturdiness and strong resistance to humidity and organic solvents. The tough coatings are resistant to mechanical wear. Additionally, Polyurethane can mitigate the growth of tin whiskers.

Polyurethane Conformal Coatings Applications

Polyurethane coatings are ideal in areas with technology that will face excessive chemical exposure.

Urethane coatings protect and insulate motors, generators, relays, transformers, and other components. This coating material is also common in automotive and aerospace environments. Urethane coatings protect these electronics from chemicals and salt sprays throughout temperature fluctuations.

Learn about protective coatings vs potting

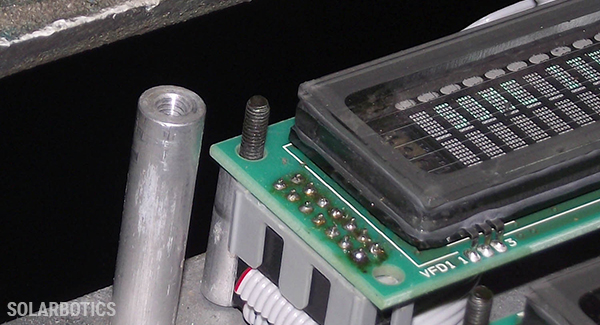

With conformal coating protection, electronic products can run reliably in harsh environments.

What Do Polyurethane Conformal Coatings Protect Against?

The coatings protect electronics from thermal shock, moisture, chemical solvents, and other elements. Compared with other materials, Polyurethane has a lower degree of friction and high abrasion resistance.

The Polyurethane Conformal Coating Process

Polyurethane is available as either single or two-component formulations and can be applied with dipping, spraying, and brushing methods. After application, the films are cured to complete the coating process which takes an hour to several days. Single-component urethanes are easy to apply but take up to days to finalize. Meanwhile, two-component formulations cure within hours. The length of the process is also related to temperature, curing faster at moderately elevated temperatures. UV curing and heat, catalyzed, and moisture curing are common methods to cross-link urethane polymers.

View a webinar about designing conformal coatings for reliability

Polyurethane Disadvantages

As we have mentioned, Polyurethane conformal coatings have benefits, such as abrasion, thermal shock, and moisture resistance. That said, the coating also has disadvantages. The curing process can be timely and requires a long post-cure time, and moisture impacts the cure rate and cured properties. The coating can also turn yellow with age.

Learn How to Choose the Best Conformal Coating for Your PCB

The Big Picture

Choosing a conformal coating material extends beyond just looking at the material and application methods. It is important to consider various variables, including the components’ complexity, environmental regulations, and coating rework and removal. Repeatable processes that avoid defects may be important, especially for high-reliability applications.

For more information on choosing the best conformal coating for your PCB, please read our definitive guide or watch one of our webinars. Alternatively, contact our Applications Engineering team for a consultation if you require more assistance. Or, you can learn more about the protection capabilities of coatings.

Parylene conformal coating by HZO does not require curing and ensures that devices, even in mission-critical applications, perform more reliably, for longer.

Mallory McGuinness

Ryan Moore

Ryan Moore

Ryan is a 9-year veteran to the world of protecting electronics from harsh environments and a lover of all things technology.

Related

Discover how HZO can protect your product