How Do You Remove Parylene Coating?

In the last blog post in our removing conformal coating series, we discussed removing conventional conformal coatings, such as polyurethane, acrylic, epoxy, and silicone, from components such as printed circuit boards. Parylene coatings, however, present unique challenges regarding rework and removal.

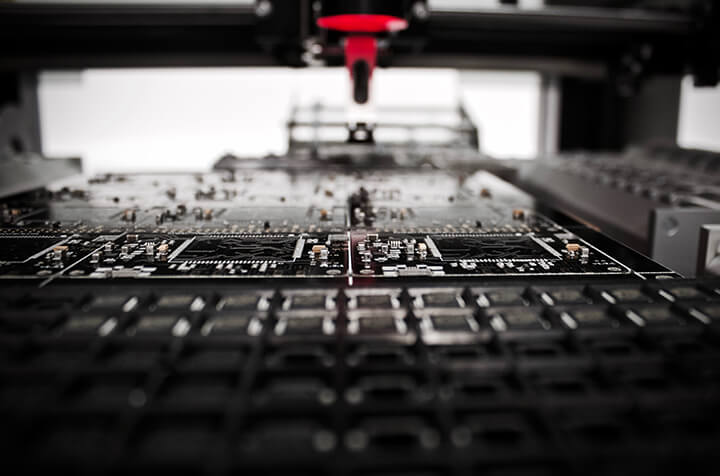

Parylene conformal coatings are unique in their ability to be polymerized and deposited by vapor deposition onto PCBs maintained at room temperature, unlike liquid conformal coating application methods that may lead to coating defects. The result is an extremely thin, pinhole-free, high-purity coating with proven performance for mission-critical applications and consumer electronics devices that must remain reliable.

Read about Parylene Type C and Parylene Type N

Parylene is often superior in barrier properties, uniform coverage, and performance in thinner layers when compared to other conformal coatings, with less stress on mechanical structures and virtually no added bulk.

Learn more about what Parylene is used for.

Additionally, Parylene has been trusted for decades due to its remarkable chemical resistance properties to withstand corrosive gases and liquids and maintain performance in extreme temperatures and intense electrical activity.

Download HZO’s Parylene datasheet

However, the beneficial properties that make Parylene the “gold standard” of conformal coating can also make the material difficult to remove. Thankfully, there are methods you can use to remove and rework Parylene when necessary.

Learn more about Parylene’s benefits, such as Parylene’s optical properties, and biocompatibility

Why is Parylene Removal Necessary?

From time to time, it is necessary to rework or remove the coating. Perhaps the job specifications changed, or a Parylene vendor incorrectly applied the coating.

One example of poor application is Parylene delamination, in which the conformal coating separates from the coated surface. This results in an unattached, torn, non-conformal coating and an unacceptable finish. Delamination defeats the purpose of Parylene conformal coatings and should be avoided at all costs. Even partial lifting can render the protective coating useless.

There are many sources of Parylene delamination, including standard processes such as demasking, which can create a need for exceptional quality control inspection procedures after production. Other causes include:

Coating porosity: When a difference in vapor pressure occurs between the component surface and the Parylene coating, this creates vulnerability to moisture permeation and intrusion into the substrate. As fluctuations of pressure and temperature subsequently occur, osmotic pressures are generated, separating the coating from the component.

Incompatible materials: The component surface and the Parylene coating must bond together for successful coverage. When the Parylene and the surface are incompatible, incongruous surface energies are generated, causing minimal bonding.

Contaminated surfaces: Improperly cleaned component surfaces do not support adhesion.

Regardless of the reason, Parylene removal must be efficient and safe to protect the integrity of the coated substrate material or component.

The following methods are popular ways to approach Parylene removal.

Mechanical Parylene Removal

Parylene’s strong capacity to withstand manipulation, exceptional uniformity, and overall strength mean that mechanical methods of removal should be used with care, as there is the potential for damage to the final production. However, as Parylene is a soft polymer, mechanical techniques can be candidates for Parylene removal.

Methods such as picking, cutting, and scraping are effective but run the risk of damaging components, substrates, and delicate track lines. This type of removal requires considerable attention and care. It is possible to achieve good spot removal with appropriate masking, but mechanical techniques may prove undependable for larger-scale surfaces.

Removing Parylene with Micro Abrasion

Micro abrasion is a process performed with automated or handheld human systems that pinpoint a targeted removal area, propelling inert gas or dry air, and abrasive media at the Parylene coating. This removal method is suitable for both whole board and spot removal. In general, it is easy to implement, quick, cost-effective, and environmentally friendly.

Thermal Removal

Although Parylene can withstand high temperatures, a high-temperature oven or soldering iron can effectively remove Parylene in specific, small areas. As heat is applied, the coated component rises from the board and then lifts off.

Although Parylene can withstand high temperatures, a high-temperature oven or soldering iron can effectively remove Parylene in specific, small areas

This technique may be adequate for small repairs. It is less reliable for large surfaces, but for particular jobs; it can still be an effective means of removal. However, residues and discoloration may occur, and due to Parylene’s high melting point, heat-sensitive substrates may be at risk for damage. Thermal removal can be challenging to manage and is not recommended without the help of Parylene experts.

Parylene Removal with Tetrahydrofuran

Parylene is chemically inert, resisting chemical degradation. However, one chemical has been used to strip Parylene from substrates and components, a colorless organic compound called tetrahydrofuran (THF), with a chemical formula of (CH2)40. This solvent softens the Parylene coating, temporarily loosening the adhesion bond between the substrate and coating. At this point, the Parylene can be lifted off with tweezers. Although THF can be successfully used to remove Parylene, caution must be taken to avoid damaging the component being coated, and the solvent should only be used for complete coating removal. For the security of components underneath the coating, it is worthwhile to consider other removal processes before using TFH.

Laser Ablation for Parylene Removal

Laser ablation is a process that removes material from a surface by irradiating it with a laser beam. The beam can cut, drill, or mark delicate materials, providing precise removal. At HZO, we have a laser ablation process in place that converts Parylene to gas or plasma with pulsed laser sources. This method can be cost-effective for complex removal jobs, results in better quality removal results, and completely Parylene-free areas and 3D devices can be effectively serviced.

Conclusion

There are multiple methods to effectively remove Parylene should the need arise. Each method has its own strengths, so it’s necessary to be aware of your options and what method will be best for your project.

If you are looking for Parylene removal services or to discuss your project with Parylene experts, please send us a message today. While removing Parylene can be challenging, if you partner with a company with the best skillsets and processes, the job can be simplified and more cost-efficient. We can also help with scalable Parylene equipment, cost-saving Parylene masking automation, and address other concerns about the cost of Parylene services.

Discover how HZO can protect your product