How can you run a more reliable and cost effective business?

Have you thought about advancements in corrosion and liquid protection? Would you like to deliver higher value to your customers and increase reliability from a company with a proven track record of performance? HZO is a company that delivers these needs.

Marketplace

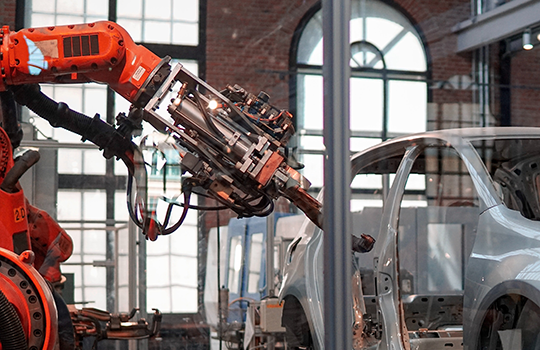

Energy & Industrial markets keep the world running smoothly as they manage critical infrastructures. The products and services in these segments enable everything from commerce, construction, and operation – benefits so diverse and vital that they have catapulted the industrial landscape into a period of incredible change.

Big-data is driving this market success. Industrial systems and appliances have been brought online to deliver smart analytics, critical information generated from machines that have optimized and modified processes to lower cost, prevent downtime, and increase safety.

By 2025, the global market size for the Industrial Internet of Things (IIoT) is expected to reach $110.6 billion.

– Marketsandmarkets

Heavy Duty Challenges for Delicate Circuitry

Although the sensors, switches, printed circuit board assemblies (PCBAs), and other components attached to your Operational Technology (OT) equipment perform robust tasks, they are physically frail. These electronic components are prone to failure when exposed to commonly harsh industrial conditions.

In a connected industrial system, if one device goes down, you could face:

- Safety issues

- Shutdown costs

- Loss of revenue

As you work to recover, the question is, are the electronics that your products depend on properly protected?

Common Industrial Failure Conditions

- Corrosive contaminants

- Water ingress

- Oil & Gas up/mid/downstream harsh environments

- Inclement weather

- Liquid submersion

- Sulfuric gases

Do you have time for downtime?

If you asked an operation and maintenance staffer for a factory, oil refinery, distribution hub, or similar industrial setting, how many times they would be willing to restart their systems, no matter what the reason, they would adamantly answer “zero.” That’s because, in industrial environments, it’s all about uptime.

The solution you use to protect your industrial devices needs to be as extreme as the environments in which your systems operate.

Durability & Reliability

- It is not common to find OT equipment as old as 50 years old still functioning.

- Your systems need to work flawlessly without human intervention for years, even decades.

- Unlike computers, which might be considered obsolete within five years, your equipment needs to run for a minimum of 10-20 years, even in harsh, outdoor situations.

Safety & Reliability Problems with Serious Consequences

When industrial devices fail, economic losses can be significant. For example:

- Contaminants that ingress into DCS controllers during oil-field maintenance can cause oil & gas companies millions of dollars in pumping-stations downtime, barrels production schedules and midstream processing costs.

-

Power companies have expenditures that can easily extend into seven figures every time an accident occurs where faulty equipment causes serious injury or death.

Are the products you’re designing truly industrial-grade?

How Failing Devices Corrode Your Bottom Line

Outages and disruptions can have large-scale impacts far beyond just your company. A power outage can affect the lives of repairing and supporting failed power equipment, as they struggle with the fundamental measure of risk that comes with working with high-voltage equipment.

For public safety, loss of electricity, water, or transportation system could be catastrophic. With consequences this dire, a proven system to protect electronics so that they are as ruggedized as the machinery they control is a mandate, ensuring they stand up to the most brutal of conditions. Yet this can be an elusive problem.

Many electronic components and PCBs operating in harsh and corrosive environments lack even the most basic protective measures.

Overcoming the Challenges with Conformal Coatings

The solution could be as simple as next-generation conformal coatings. Super thin-film materials, thinner than a strand of human hair, ensure your electronics keep working as hard as you do. Our HZO branded series of solutions are the next-generation of leading protective coatings:

What it means to be truly protected

HZO defines “truly protected” as knowing your electronics, whether at a component, board or device level will perform as you designed, come rain, sweat, steam, caustic gases, and more. We do this by drawing from an IP portfolio of over 370 assets.

These assets allow us to offer a tailored approach to meet your protection requirements. It is this very reason that Fortune 100 companies and leading–edge businesses place their products in our hands. Not to mention that since our inception, there have been zero customer warranty claims attributed to coating issues.

Delivering Real Value

Working For You

When you partner with HZO, you’ll never be left feeling pigeonholed into an “either-or” situation where you have to settle. We work until we find a solution that meets your needs.

A Perfect Pairing

Our passion for partnering to serve you the best solution drives our ongoing research and innovation so that we can continue to create something ideal, rather than simply provide a generic solution that delivers less than you should expect.

Industry Specific

HZO knows the inner workings of the connected industrial marketplace and understands the consequences of a single sensor failure, DCS fault, or automation error. No reason to be a coating expert, we provide a complete turnkey solution with guaranteed results.

Look No Further

Our turnkey solution combines deep domain expertise, patented processes, material science, and proprietary machinery to deliver a repeatable, scalable, solution customized for you.

Protection Partner

We partner from product inception to mass production, providing design for excellence (DFX) guidance to help ensure manufacturability, cost optimization, and proven performance.

A Business Model To Match Yours

We work around your business, offering coating as a service in factories built from the ground up for scalability or can bring our technology to you as part of our Factory-in-Factory business model.

10x Your Production

HZO can coat ten units or tens of thousands of units a day. If you are looking for mass-scale production, we are one of the only vendors in our industry who can do so within a budget and deadline.

Scale You Can Afford

You always have the option to scale for mass production with us, which can be less expensive than other types of coating processes at a cost per unit level.

Throughput Squared

We built proprietary coating equipment with the largest chambers in the industry that have a unique square shape, allowing us to coat more devices at once, which means more scalability for you.

Just What The Engineer Ordered

Our Spectrum of Protection portfolio allows us to create protective films tailored for your electronics, from the durability of Parylene to the customization and competitive price point of Plasma-based nanocoatings and hybrid alternatives.

Segments We Serve

The global distributed energy generation (DEG) market size is expected to reach $573.7 billion by 2025.

Distributed Energy and Industrial

The power utility and industrial segments have been transformed beyond recognition by disruption from new distributed energy resources (DER).

- Distributed generation

- Electric vehicles and charging stations

- Energy storage

- Smart cities

With HZO protection, products such as digital logic controllers used to protect and control critical power and automation platforms can achieve high levels of reliability, minimizing risks and liabilities from downtime and failure rates.

Digital Grid and Distributed Energy Resources

Utility grids have undergone a dramatic shift from the traditional centralized, unidirectional energy generation, transmission, and distribution systems, to “decentralized,” “decarbonized,” and “digitalized” models.

When PCBs, circuitry, and electronic components embedded in key DERs platforms have HZO protection:

- (Hybrid) microgrids can provide clean, distributed power to off-grid critical applications.

- EV charging stations can guarantee grid balancing and optimized load management.

- Renewable energy storage and inverters can offer solutions for small-industrial, commercial, and residential applications.

- Smart meters and smart cities applications can run reliably and smoothly.

Worldwide, the smart grid market to is projected to grow to $61.3 billion by 2023.

The global IoT in the oil and gas market will be valued at $39.40 billion by 2023.

Oil, Gas & Chemicals and Mining

Implementing intelligent OT edge in harsh industrial environments, requires IIoT connectivity and control platforms to operate with the highest level or reliability and resiliency.

This is particularly true in critical power, automation and IoT networking platforms such as:

- Distributed Control Systems (DCS)

- Controllers and I/O modules

- UPS systems

- Protection and control relays and IEDs

- Variable-frequency-drives

- Flowmeters and sensors

- Pipeline pigs sensors

- Rugged Ethernet Routers and Switches

Discover how HZO can protect your product