Does your business want to build safer, more reliable products that countless lives depend on?

Are you looking for a partner who will put blood, sweat, and tears into protecting your medical devices and electronics from liquid threats? Do you want to reduce risk and set your product apart?

For medical device manufacturers and designers (MDMs), reliability is a differentiator in a marketplace brimming with growth and competition. Our coatings for medical devices can help you achieve this.

Marketplace

The medical devices market is expanding to meet the demands of chronic disease and an aging population. By 2025, this global industry will be valued at $612.7 billion. But as opportunity increases, so does the level of competition.

To rise above the rest, you’ll need to offer a product that your customers can truly depend on.

After all, in this market, there is no room for “good enough” devices. If a connected, smart speaker breaks, that’s an annoyance; if a glucose monitor fails, that’s a crisis. Meeting medical technology’s standards of excellence is a challenge, but designing products that rise to the occasion is possible.

By 2025, the global medical device industry will be valued at $612.7 billion.

– Fortune Business Insights

Challenges for Medical Excellence

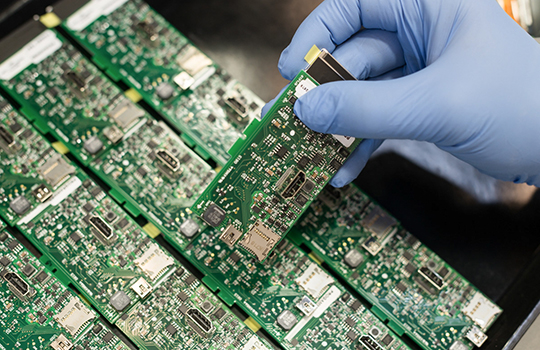

You can provide more reliability by protecting the electronics that run and manage medical devices from physical harm with conformal coatings.

Water, sweat, bodily fluids, medicine, and cleaning liquids are just as destructive to electronics as they are common. Liquids can short circuit devices, resulting in immediate failure, or they can cause corrosion, which creates a more extended, unexpected breakdown.

A single splash or spill can cause devices to fail, resulting in loss of data, product returns, and potential harm to consumers. Protecting your devices is more important than ever, but the real challenge is that traditional methods used to do this fall short while parylene coatings for medical devices are leading the way.

Common Medical Electronics Failure Conditions

- Water

- Sweat

- Bodily Fluids

- Medicine

- Cleaning Liquids

Overcoming the Challenges With Medical Device Conformal Coatings

Enclosures, such as cases and seals, can easily break after a drop or simply wear out with time, making long-term reliability impossible. Meanwhile, typical conformal coatings can be bulky and heavy and require curing to be effective.

Overcoming these challenges can be as simple as reaching out to HZO. We offer next-generation thin-film conformal coatings that take protection to a higher level. Our medical device coatings have the capability to protect your product from water, corrosion, humidity, sweat & much more!

We offer four types of coatings that protect your electronics:

Reduce Risk with True Protection

Our diverse medical device coating product lines offer a variety of benefits to suit most needs. After partnering with us, you will come to believe that if it doesn’t say HZO, you aren’t truly protected.

Don’t just take our word for it – check the record. Since our inception, there hasn’t been a single return attributed to coating issues. Our global customers, Fortune 100 companies, and trailblazing businesses are valuable to us, which is why we never let them down.

Medical Device Coating Company That Delivers Real Value

Along with our proven history, we bring serious benefits to the table that no other vendors can provide. Choose us, and you’ll be able to:

Select The Most Convenient, Efficient Solution

Choose between our Factory-in-Factory business model or our coating as a service offering, where we coat your devices in one of our manufacturing facilities.

Reduce Uncertainty With Prescriptive Outcomes

Our team of dedicated application engineers has the expertise to meet specified outcomes. You’ll never have to feel unsure that you made the right choice.

Bring Products To Market Faster

We invest in scalable, proprietary coating equipment built to meet your mass production needs, even within a budget or time constraint.

Keep Costs In Check

Corrosion-related recalls, repairs, and warranty claims can be costly. Proactively prevent these expenses with protection that can stand up to sweat, bodily fluids, and blood that is thicker than water.

Segments We Serve

Diabetes Devices

1 in 11 adults worldwide is currently living with diabetes. Diabetes devices, including glucose meters and insulin pumps, have come a long way. But as advanced as these devices are, they are still vulnerable to splashes and spills.

Diagnostic Imaging Devices

The global market for diagnostic imaging is currently estimated to be around $40 billion. We protect devices such as EEG analyzers that are exposed to bodily fluids and water every day.

Hearing and Vision Aids

Over 900 million people will experience hearing loss by 2050. The electrical components inside these high demand devices can be as small as a pencil eraser. For parts this small, bulky mechanical seals and thick conformal coatings are not an option.

Other Medical Devices

Our protection can extend to different types of medical devices as well, including dilators, blood mixing and weighing devices, “drug delivery devices,” and catheters.

Each MDM has different requirements and needs, which is why we offer custom solutions to meet your most important requirements. Here at HZO, we protect a variety of medical devices with one big thing in common: failure is not an option. Just what the doctor ordered.